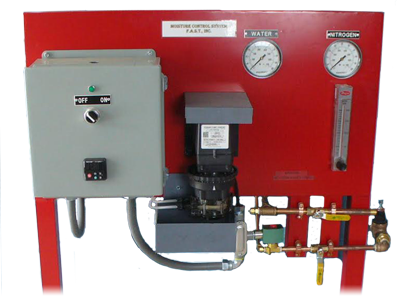

The panel was designed to produce a continuous and constant flow of water into a stream of noncombustible gas to produce an atmosphere with a constant dew point on a 24 hour, 7day a week schedule. The panel is equipped with a precise water metering pump, nitrogen flow meter, a heating unit, and an electrical box that contains a digital temperature controller w/ high and low temperature shut-offs, and an audio alarm system. The panel also comes with a water pressure regulator, a pressure relief valve, and an installation and operating manual. The precise water metering pump allows the dew point in the furnace to be raised or lowered and still remain constant, regardless of your application.

To date, this panel has been used very successfully in removing carbonaceous vapors from the preheat zone of continuous belt furnaces used for sintering ferrous and non-ferrous powdered metal compacts. However, it very obviously could be used in any application that requires a moisture additive on a continuous basis such as, annealing, brazing, and some oxidizing processes.

Whether you are trying to remove carbon from the material or from the furnace, this unit will definitely be of value in your process. In the sintering of powdered metal compacts it has proven to increase the belt and muffle life by as much as 33 to 50% as well as increase production time, reduce maintenance costs, and reduce stack emissions. This is accomplished by maintaining a soot free furnace.

For more information and orders please contact us at: info@fast-inc-pmt.net